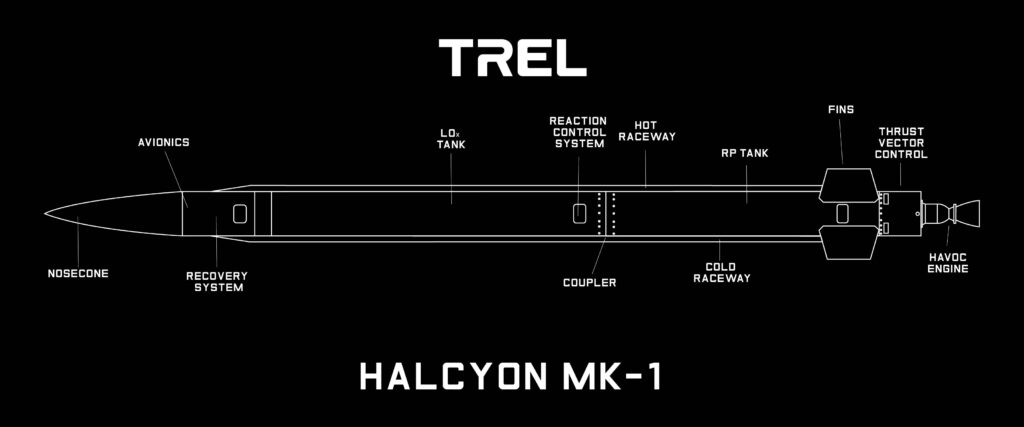

Halcyon

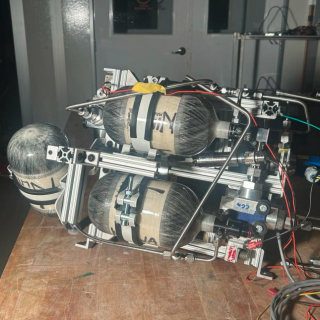

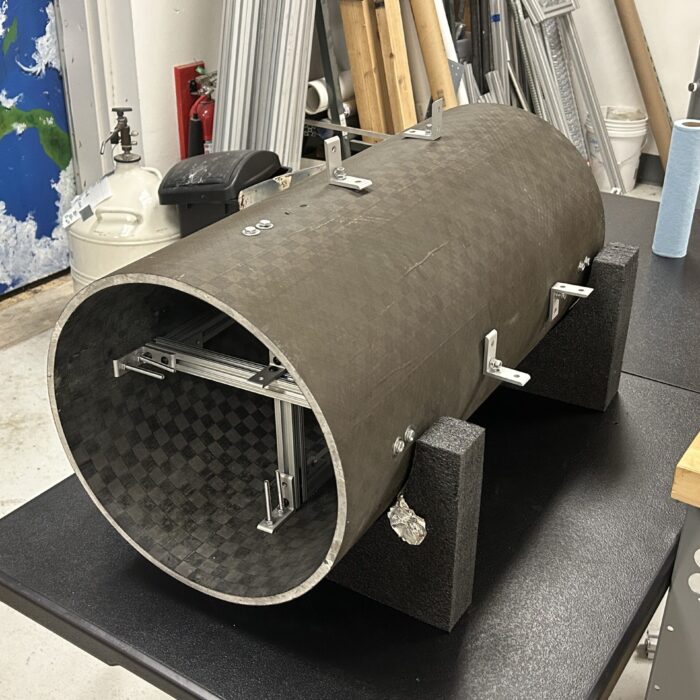

Halcyon is TREL’s premier launch vehicle, a liquid bi-propellant rocket. Halcyon MK1 possesses two Composite Overwrapped Pressure Vessel tanks (COPVs). Halcyon is also guided by a Thrust Vector Control (TVC) system. Each hardware and software component of this rocket is designed and evaluated by TREL members under the guidance of industry experts and alumni.

MK1

Simplified hardware configuration with blowdown pressurization system. Use the 2x LOx/RP-1 COPVs we have on hand that we previously used for pressure cycle testing. Start integration immediately and aim to fly Spring 2025 to double the collegiate altitude record.

Test and Launch

Test and Launch

Test and Launch focuses on the development and operation of the Ground Support Equipment (GSE) and all other infrastructure that validate Halcyon’s mission from prior to integration all the way up to launch. The Test and Launch department consists of three test stands – The Engine Test Stand (located at Briggs TX) used to hotfire our engine, and validate the Engine Team’s designs. The Vehicle Test Stand used to static fire and launch our vehicle, and various smaller test stands located at our pickle research campus used to validate all the components that will eventually fly on MK1, and future iterations of Halcyon.

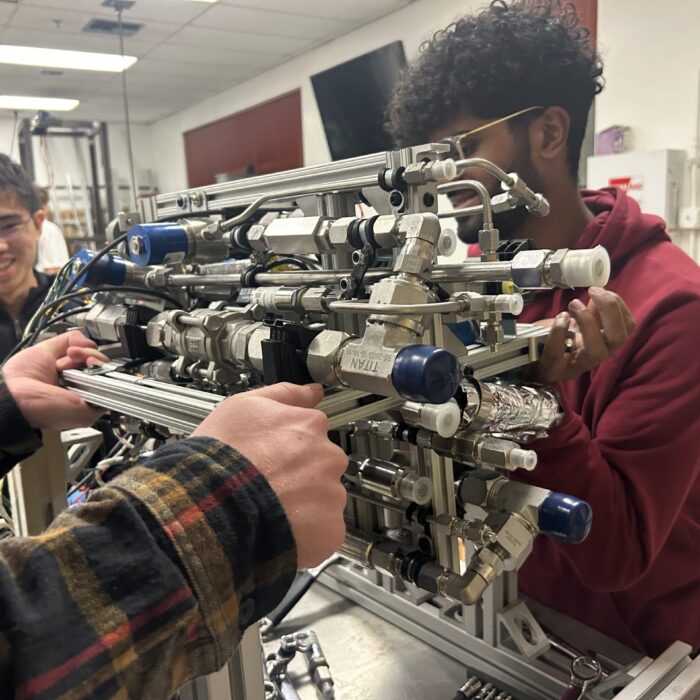

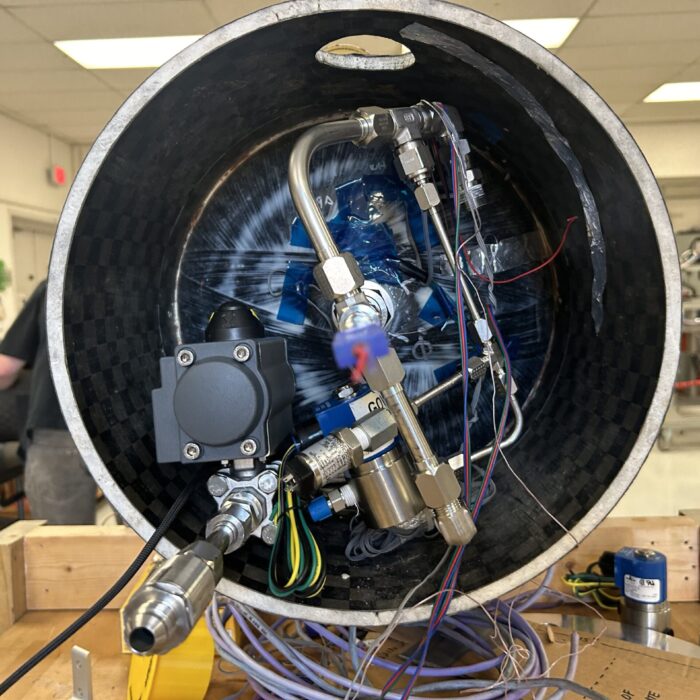

Propulsion

Propulsion

Propulsion focuses on the systems that power Halcyon and ensure its successful operation. At the heart of Halcyon is Havoc, its RP-1/LOx bipropellant engine – which is developed, tested, and integrated by the Engine team. The Fluids team is responsible for the systems that deliver propellant to Havoc, ensuring efficient performance. Additionally, the Propulsion team oversees the Thrust Vector Control system, which directs Halcyon’s flight trajectory.

Structures

Structures

The Structures teams are responsible for designing, manufacturing, and integrating Halcyon’s structural components and recovery system.

Avionics

Avionics

The Avionics Team is responsible for the designs, manufacturing, and integration of every electrical component, from power converters to wire harnesses to RF systems.

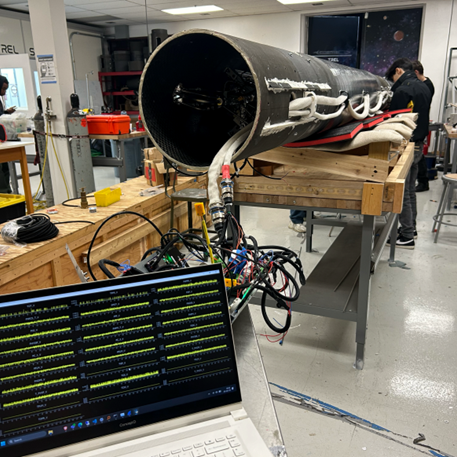

Ground Station Software

GSW

The Ground Software team is responsible for building and deploying the software for Halcyon’s test and launch operations.

Infrastructure

Infrastructure

Infrastructure is responsible for designing and building the tooling necessary to integrate andlaunch Halcyon as well as logistical plans for test and launch.

Guidance Navigation and Control

GNC

The Guidance, Navigation, and Control (GNC) team is primarily tasked with determining the ideal flight path for the vehicle, estimating the vehicle’s state throughout the flight, and ensuring that the vehicle remains stable along its nominal trajectory. Members of the team use Simulink and C++ to create a computer model of Halcyon’s flight control theory to build and then use control theory to build algorithms that will actively control the rocket in flight.

Recovery

Recovery

Recovery has several mission critical responsibilities including but not limited to the safe recovery of Halcyon. Our major projects include 1) The design and fabrication of the nosecone and the rocket’s only separation system. 2) The development of the 2-stage vehicle recovery system and nosecone recovery system. Our members gain various experiences – including the development and testing of relevant circuits and GPS tracking systems for our components.

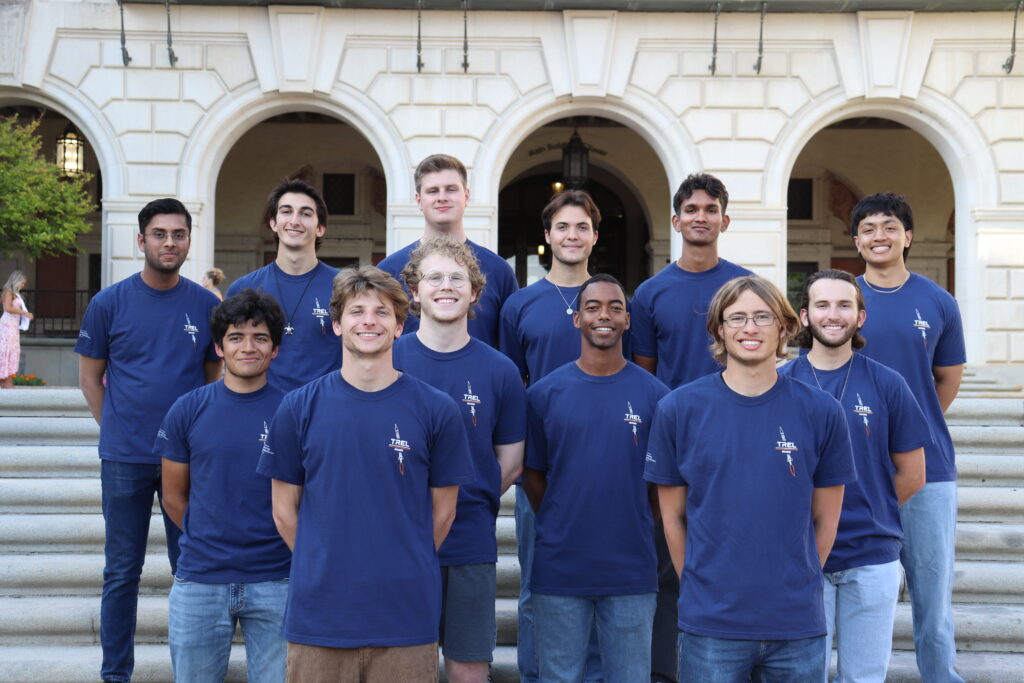

Halcyon Spring 2025

Halcyon Leadership Spring 2025

![IMG_2112[1]](https://texasrocketlab.ae.utexas.edu/wp-content/uploads/2025/02/IMG_21121-700x700.jpg)