Neptune3

The next step to collegiate orbit.

Neptune3 is TREL’s next generation launch vehicle, an electric pump-fed multi engine rocket. The Neptune3 vehicle has two COPVs for propellant, and uses an active pressurization system. Neptune3 utilizes a composite airframe, and multi-engine TVC for active control during flight. Neptune3 is an unprecedented vehicle for collegiate rocketry as TREL embarks on its path to orbit.

Mechanical Systems

Mechanical Systems

The Mechanical Systems team works on projects such as the Thrust Vector Control (TVC) System, the aft end thrust structure, release mechanisms, and rocket activation.

Propulsion

Propulsion

The Propulsion team comprises the Stage Fluids and Riptide Engine sub-teams. The Stage team develops the vehicle fluid system throughout the three intertanks, while the Riptide Engine team develops our electric pump-fed engine.

Composite Structures

Composite Structures

The Structures team is responsible for the overall vehicle structural architecture and test. This team is responsible for determining the test procedures and requirements for structural tests, as well as the requirements for overall vehicle architecture.

Composite Manufacturing

Composite Manufacturing

The Composite Manufacturing team is responsible for the manufacturing of the composite structures on the rocket. These structures include the composite airframe, the bonding of the airframe to COPVs, the nosecone, the joints between airframe sections, and the raceways.

Flight Software & Ground Software

FSW & GSW

The Flight Software team develops the on-vehicle software architecture, developing systems that allow for effective communication and control of the different hardware components components including valves, electric pumps, the GPS, and IMU.

The Ground Software team develops the software related to the control of Ground Support Equipment and the interface with the vehicle. This software architecture is used to conduct tests and activate the vehicle for launch.

Avionics

Avionics

The avionics team is responsible for the electrical hardware components of the vehicle, including the pump controller, GPS, IMU, sensors, flight computers, and control of the TVC system.

Guidance, Navigation, and Control

GNC

The GNC team is responsible for the development of simulations modeling vehicle trajectory, the development of abort cases, and the development of controllers for active control systems on the vehicle, such as the TVC system, the RCS system, and engine throttling.

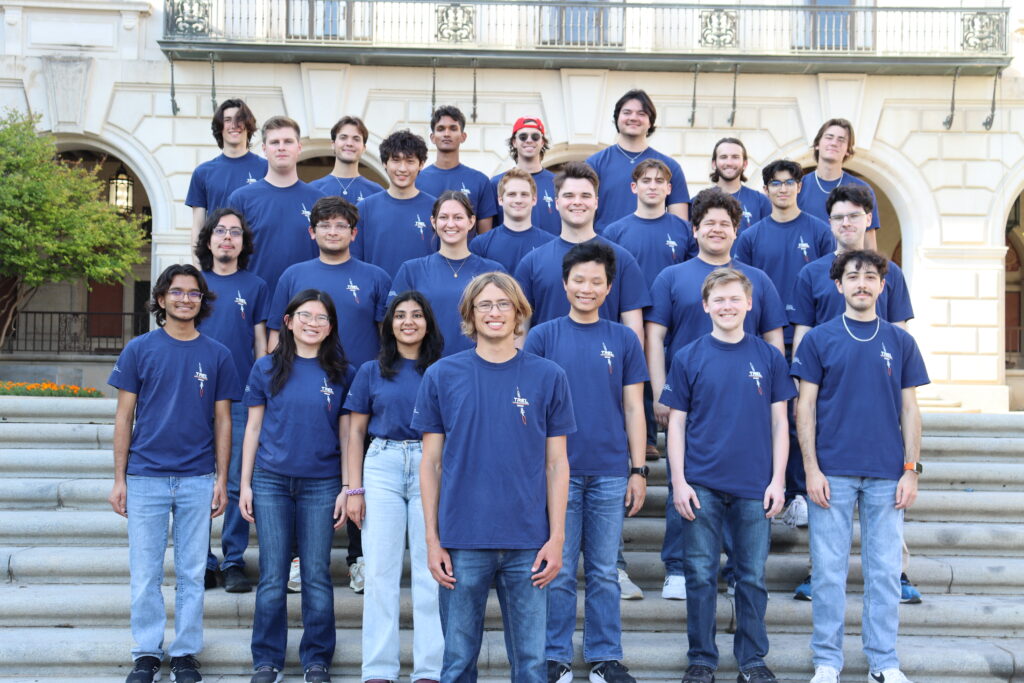

Neptune3 Spring 2025

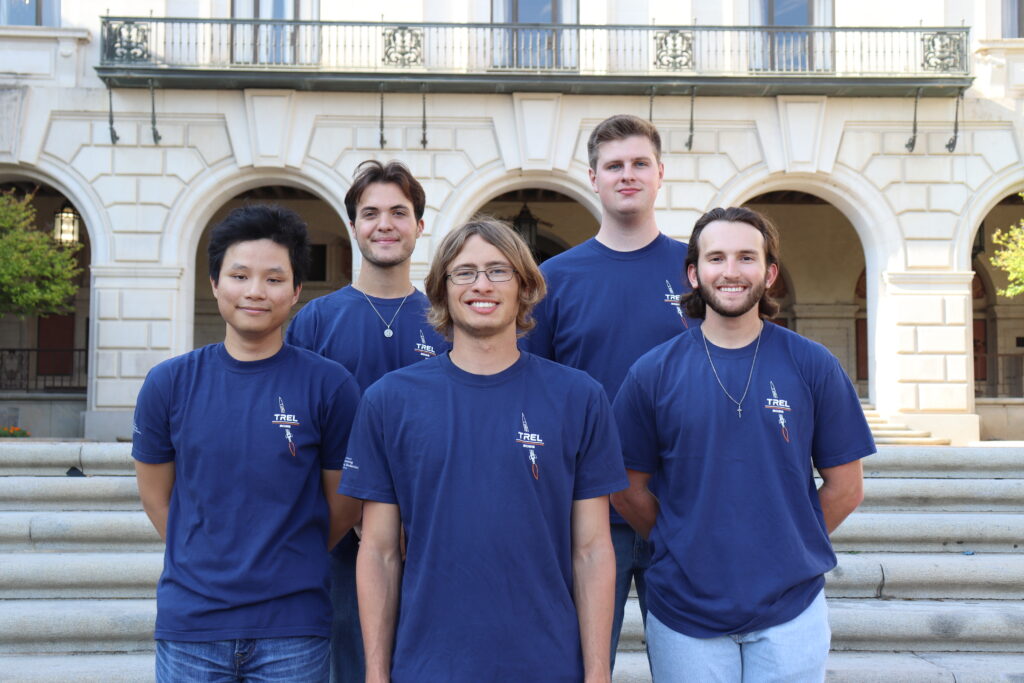

Neptune3 Leadership